MSc thesis project proposal

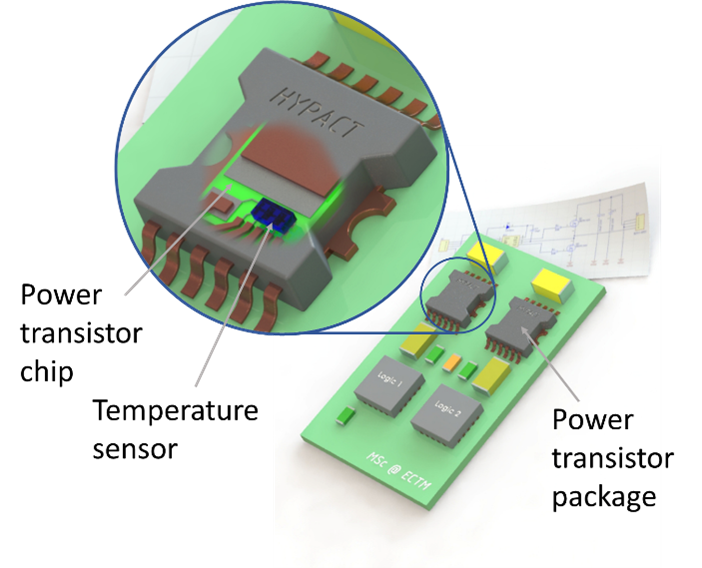

Smart power package

The energy system becomes more diverse with intermittent renewable electrical energy sources such as wind and solar power, and storage such as hydropower and batteries added to the grid. Consequently, more control is required over the electrical energy flow throughout the entire grid. In this energy diversification, novel wide bandgap semiconductor power transistors with increased power density capabilities plays a key role at all levels in the electrical energy system. The power density in such transistors also brings challenges, such as higher operating temperatures in the microelectronic package. This leads to thermal mechanical stresses, accelerated aging, and reliability problems.

One method to overcome these problems is to regulate the power through the transistor based not only on the output requirements of the circuit, but also on the internal temperature of the transistor. For example, if the temperature rises too high, a control circuit can reduce the output power of the transistor. However, transistor temperature measurement is currently based on indirect methods such as PCB-level temperature measurement, which leads to inaccurate and time-delayed measurements.

The scope of this project is to develop a system-in-package (SIP) in which a temperature sensor chip is integrated with the power transistor chip using a novel interconnect process. To prove the concept, the SIP is assembled on a PCB together with the required control electronics to de-rate the power output if the temperature is increased above certain levels. The power transistor used in this project can be a commercially available bare chip or an in-house produced thermal test chip to mimic the thermal performance of a high-power transistor.

Assignment

The duration of the project is 9 to 12 months (45 to 60 ECTS).

The project will involve the following tasks:

- Literature study to assess the state of the art.

- Select a power transistor and/or thermal test chip for the project.

- Define sensor requirements (sensitivity, EMC compatibility…).

- Select a temperature sensing method.

- Design a control circuit and corresponding PCB.

- Desing an integration flowchart based on a novel nanometallic interconnect process.

- Sensor chip fabrication in the EKL cleanroom and chip assembly/packaging in the ECTM laboratory.

- Characterise the system performance.

- Reporting.

Requirements

Interested students can contact Dr. Henk van Zeijl at h.w.vanzeijl@tudelft.nl

Last modified: 2024-01-12