MSc thesis project proposal

[2024] Integrated Circuits and Systems for Vibration Energy Harvesting

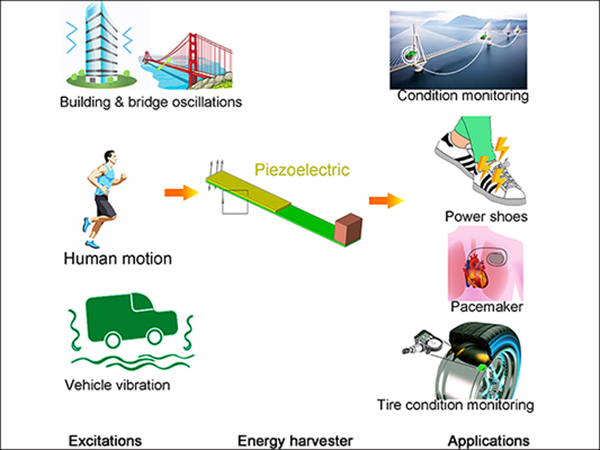

Along with the development of the Internet-of-Everything (IoE), wireless sensing networks (WSN) play essential roles in interconnecting the real world and the Internet. Although electrochemical batteries have remained the primary energy sources for such systems due to the high energy density, certain sensors and sensor systems require to operate over significant periods of time much longer than the lifetime of electrochemical batteries. Battery usage may be both impractical and costly due to the requirement for periodic recharging and/or replacement. In order to address this challenge and extend the operational lifetime of wireless sensors, there has been an emerging research interest in harvesting ambient vibration energy to the power IoE devices implemented in an environment where kinetic vibration energy exists, such as airplanes, cars, bridges, buildings, etc.

In this context, piezoelectric energy harvesting (PEH) has emerged as a particularly promising solution due to its inherent advantage of high power density. By harnessing the conversion of vibration energy into electrical energy, PEH offers a viable alternative to traditional bulky batteries in IoT applications, thereby addressing the limitations of limited battery life and frequent replacements. In this project, we are going to design a piezoelectric energy harvesting system, that can harvest the kinetic vibration energy while achieving high reliability, high output power, and regulated output voltage. We are going to design a novel highly integrated energy-harvesting ASIC with a new energy conversion topology and architecture to minimize the system form factor while achieving great performance.

Reference:

[1] Y. K. Ramadass and A. P. Chandrakasan, "An Efficient Piezoelectric Energy Harvesting Interface Circuit Using a Bias-Flip Rectifier and Shared Inductor," IEEE Journal of Solid-State Circuits, vol. 45, no. 1, pp. 189-204, 2010, doi: 10.1109/JSSC.2009.2034442.

[2] S. Du and A. A. Seshia, "An Inductorless Bias-Flip Rectifier for Piezoelectric Energy Harvesting," IEEE Journal of Solid-State Circuits, vol. 52, no. 10, pp. 2746-2757, 2017, doi: 10.1109/JSSC.2017.2725959.

[3] X. Yue and S. Du, "A Synchronized Switch Harvesting Rectifier With Reusable Storage Capacitors for Piezoelectric Energy Harvesting," IEEE Journal of Solid-State Circuits, vol. 58, no. 9, pp. 2597-2606, 2023, doi: 10.1109/JSSC.2023.3260145.

[4] X. Yue, S. Javvaji, Z. Tang, K. A. A. Makinwa, and S. Du, "30.3 A Bias-Flip Rectifier with a Duty-Cycle-Based MPPT Algorithm for Piezoelectric Energy Harvesting with 98% Peak MPPT Efficiency and 738% Energy-Extraction Enhancement," in 2023 IEEE International Solid- State Circuits Conference (ISSCC), 19-23 Feb. 2023 2023, pp. 442-444, doi: 10.1109/ISSCC42615.2023.10067284.

Assignment

1. Literature review of energy harvesting integrated circuits and systems.

2. Design and tape out a highly efficient, fully integrated interface circuit in 180nm BCD technology.

Requirements

You should be familiar with analog IC design and Cadence environment. If you are interested, please send the following documents to Sijun Du at email: Sijun.Du@tudelft.nl

- Your up-to-date CV

- BSc transcripts

- MSc grades (obtained to date)

Suggested courses to appear in your IEP:

- Analog Circuit Design Fundamentals

- Measurement and Instrumentation

- Analog CMOS Design 1 and 2

- Digital IC Design 1 and 2

- Analog Integrated Circuit Design

Not a must in your IEP, but you are encouraged to learn some course materials at least:

- Nyquist-Rate Data Converters

- Power conversion techniques in CMOS technology (Only the SMPC and SCPC parts)

- Semiconductor Device Physics

Contact

dr. Sijun Du

Electronic Instrumentation Group

Department of Microelectronics

Last modified: 2024-06-11